汽車智慧倉儲升級專案計畫

製造企業

提高營運效率

提高決策效率

節省超過 6 百萬的成本

減少工作場所意外

項目背景

汽車供應鏈倉儲面臨著極為複雜的挑戰和零容忍的要求。它必須準確回應生產線的準時 (JIT/JIS) 供應,以避免昂貴的停機損失。.

平衡兩種相互衝突的營運模式:

高週轉生產材料

大量低頻售后備件

客戶痛點

1.空間利用瓶頸:

狹窄的車間走道限制了傳統設備,導致空間利用率低。.

2.勞工效率與成本壓力:

手動處理效率低且成本高,難以滿足生產速度。.

3.管理盲點與可追蹤性挑戰:

手動處理缺乏資料記錄,造成物料狀態不透明及可追蹤性不足。.

4.系統協調與整合的挑戰:

複雜的現場設備佈局包含多個移動路徑,因此必須進行路徑交通管理和設備互鎖。.

解決方案配置

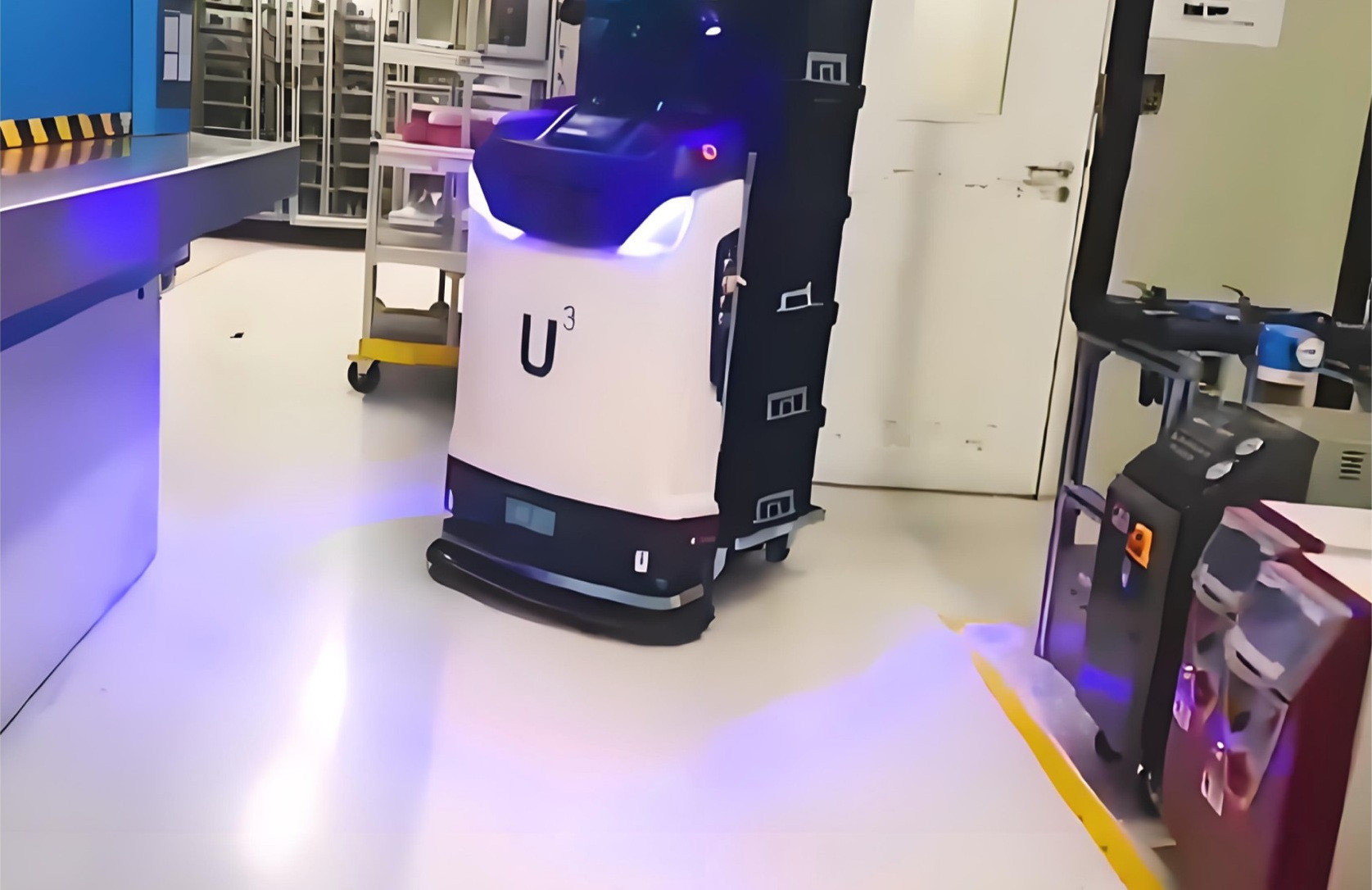

- 部署了 30 台混合運輸機器人,整合了 WCS 設備停靠系統和 RDS 排程系統。.

- 透過即時資料擷取,系統 實現了端到端的可追溯性和材料流的可視化管理, ,實現高效率的協同自動化物料處理。.

客戶利益

1.效率提升:

營運效率提高了超過 50%,材料交貨量和處理量大幅成長。.

2.成本最佳化:

每年節省成本超過 600 萬元,大幅減少材料浪費。.

3.管理升級:

實施資料驅動管理,提高決策效率 40%,同時維持整潔有序的工作場所。.

4.安全與永續性:

工傷率降低了 99.9%,實現了 「人為操作傷害為零」。“

服務

我們提供多種 raas

服務計劃

- 所有

- 澳洲

- 中國

- 日本

- 韓國

- 馬來西亞

- 新西蘭

- 新加坡

- 泰國

- 越南

輪胎倉儲專案

本專案旨在為一家知名輪胎製造商打造領先業界的端對端自動化解決方案。該解決方案涵蓋輪胎生產的所有關鍵階段、,

汽車零件倉儲專案

某知名汽車零件製造商為了應對日趨複雜的供應鏈管理並提高生產效率,決定將現有的半成品倉庫全面升級為高效率的現代化倉庫、,

領先上市汽車零件公司的智慧倉儲專案

我們成功地為一家領先的汽車零部件上市公司規劃並實施了一套高度智能化的倉庫管理系統。該專案旨在通過整合先進的自動化設備和智能控制技術,革新其內部物流系統,全面提高物流效率,降低運營成本,並顯著提升整體信息化水平。.

汽車內飾系統公司

這家全球領先的汽車內飾系統公司專注於汽車內外裝飾、汽車座椅、車廂電子和被動安全等核心領域。自 2010 年積極拓展海外市場以來,該公司已成功重組並發展成為全球最大的汽車內飾企業。目前,該公司在全球擁有 230 多家工廠,員工...

數位汽車工廠

一家知名的數字汽車工廠,專注於BMW品牌汽車在中國市場的全價值鏈運營,涵蓋從研發、採購、生產到銷售、售後服務的各個環節。它不僅致力於成為可持續發展的優質個人出行服務供應商,更引領可持續發展的...

某知名汽車組裝零件 KLT 倉庫

隨著汽車行業的快速發展,某知名汽車零部件製造商對其成都基地的 KLT 倉庫的自動化和智能化提出了更高的要求。為了打造智慧倉庫,提高整體運營效率、,