PROJECT BACKGROUND

3,300㎡ storage space

Conveyor line operating capacity

Cache shelf operation capabilities

Picking accuracy

Project Pain Points

Complex Material Types: Numerous companies within the park handle various raw materials, semi-finished products, and finished products, making management challenging.

High-Standard Management Requirements: Higher requirements are placed on environmental protection, energy consumption, safety, and efficiency.

Space Utilization Challenges: Traditional warehousing models struggle to meet high-density storage and future expansion needs.

Supply Chain Collaboration Efficiency: Bottlenecks exist in material flow and information sharing among companies within the park.

Solution

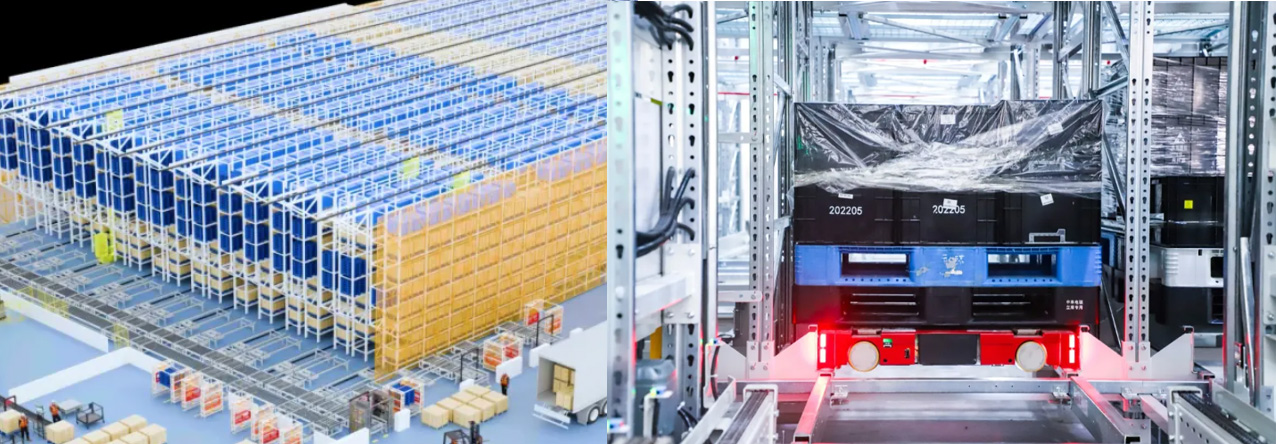

Solutions: Multi-directional shuttle solution, aisle space solution.

Stacker crane and four-way vehicle dual-system collaboration: Precisely manages over 10,000 storage locations, ensuring high-density storage and efficient retrieval.

Stacker crane automated storage and retrieval system (AS/RS): Capable of handling high-speed, large-volume material processing with an inbound capacity of 184 pallets/hour and an outbound flow rate of 172 pallets/hour.

Four-way vehicle high-density storage area: Equipped with manual picking stations, efficiently handling frequently used small items (up to 34 pallets/hour), while also supporting direct docking of forklifts and AGVs with the production line for handling full cases of materials, achieving seamless integration.

Circular conveyor line: With a bidirectional flow rate of 73 pallets/hour, precisely adapting to the diverse, small-batch manufacturing needs within the park, offering flexibility and efficiency.

Customer Value

Automated Inbound Processing, Leap in Efficiency: Each inbound gate is equipped with a shape detection and fixed four-sided barcode scanning system, enabling automated inbound processing without manual scanning. The system automatically recognizes barcodes, binds child pallets to parent pallets, and uploads tasks, effectively saving significant manual time, significantly improving production line inbound efficiency, and completely solving the customer’s inbound/outbound and inventory management challenges.

Precise Production Line Support: A circular conveyor system is used in front of the warehouse for buffering, currently capable of holding up to 70 pallets of goods. This significantly accelerates the flow and retrieval of goods, effectively addressing the material needs of the production line during peak periods and providing a solid guarantee for customer production line operations.

High-Density Storage, Optimized Space: Dual systems work collaboratively to maximize the use of warehouse space and support the sustainable development of the park.

Green and Intelligent Operation: Reduced human intervention and optimized energy consumption align with the green development concept of the dual-carbon industrial park.